Pump Housing: Usually made of cast iron or aluminum alloy. Cast iron has good strength and durability, enabling it to withstand the pressure and temperature within the engine cooling system. Aluminum alloy, on the other hand, offers better heat dissipation and a lighter weight.

Impeller: Generally made of brass or high - strength plastic. Brass impellers are corrosion - resistant and more efficient in fluid transfer. High - strength plastic impellers can provide reliable performance under normal operating conditions and are cost - effective.

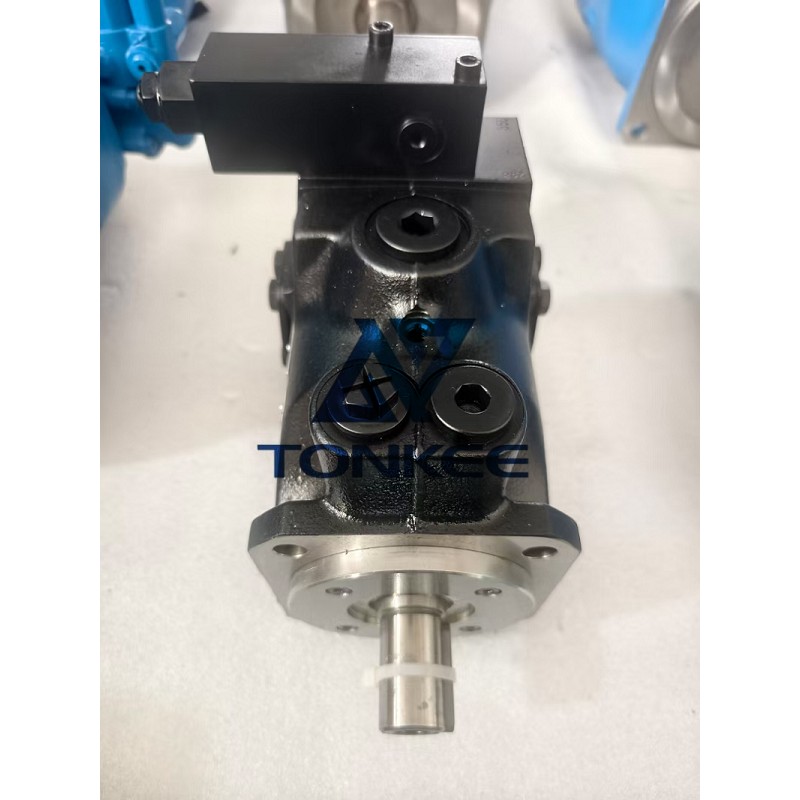

Shaft and Bearings: The pump shaft is often made of stainless steel, which has good mechanical strength and corrosion resistance. The bearings are used to support the pump shaft and ensure its smooth rotation. They are usually sealed to prevent contaminants from entering and can withstand the loads and speeds associated with the pump's operation.

Seals: High - quality seals are used, typically made of rubber or synthetic materials. These seals can withstand the temperature and chemical properties of the coolant, effectively preventing coolant leakage and being crucial for maintaining the integrity of the cooling system.