Firstly, both the EIPC3-040RA23-10 and EIPC3-050 pumps belong to the gear pump category, which is a positive displacement pump type.

They operate by using interlocking gears to create suction and discharge pressure. These pumps are particularly suited for hydraulic systems that require a steady flow of fluid at a constant pressure.

The EIPC3-040RA23-10 is a model with a displacement of 40 cm³/rev, while the EIPC3-050 has a displacement of 50 cm³/rev. Displacement refers to the volume of fluid displaced by the pump per revolution. This specification determines the flow rate of the pump.

These gear pumps are designed to handle a wide range of hydraulic fluids, including mineral oils, synthetic oils, and water-glycol mixtures. The materials used in their construction ensure compatibility with different fluids, allowing for versatile application in various industries.

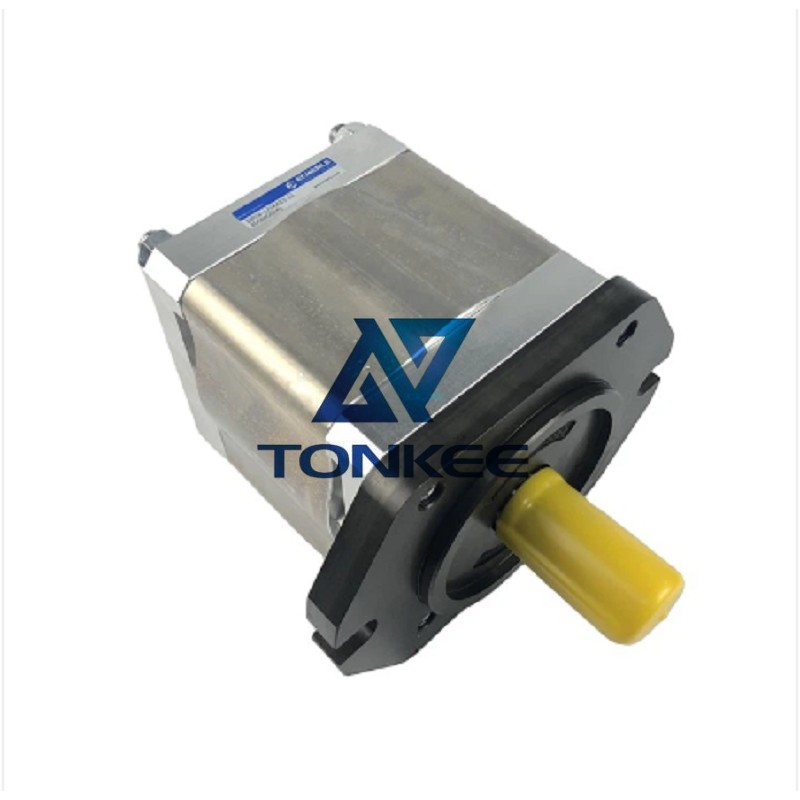

One key feature of these pumps is their compact and lightweight design. This makes them easy to install and integrate into hydraulic systems with limited space. Despite their small size, these pumps deliver excellent performance and can generate high pressures, typically up to 250 bar (3626 psi). This feature makes them suitable for demanding applications that require high-pressure fluid delivery.

To ensure smooth operation and reduce noise, the EIPC3-040RA23-10 and EIPC3-050 pumps are equipped with precision-machined gears and high-quality bearings. These components minimize internal leakage and friction, resulting in improved efficiency and quieter operation.

Both models are built with robust housings and shafts to withstand high loads and provide long-lasting durability.

They are designed to operate continuously under demanding conditions, making them suitable for industrial environments where reliability is crucial.

The EIPC3-040RA23-10 and EIPC3-050 pumps can be configured with different mounting options, such as flange or foot mounting, to accommodate diverse installation requirements. This flexibility allows for easy integration into existing hydraulic systems or new applications.

Additionally, these pumps are designed for ease of maintenance. They feature a modular construction, enabling quick and straightforward replacement of wearing parts, such as seals and gears, without disassembling the entire pump. This minimizes downtime and reduces maintenance costs.