Manufacturer: Sauer Danfoss

Hydraulic Pump Series: SPV22, SPV23, SPV24, SPV25

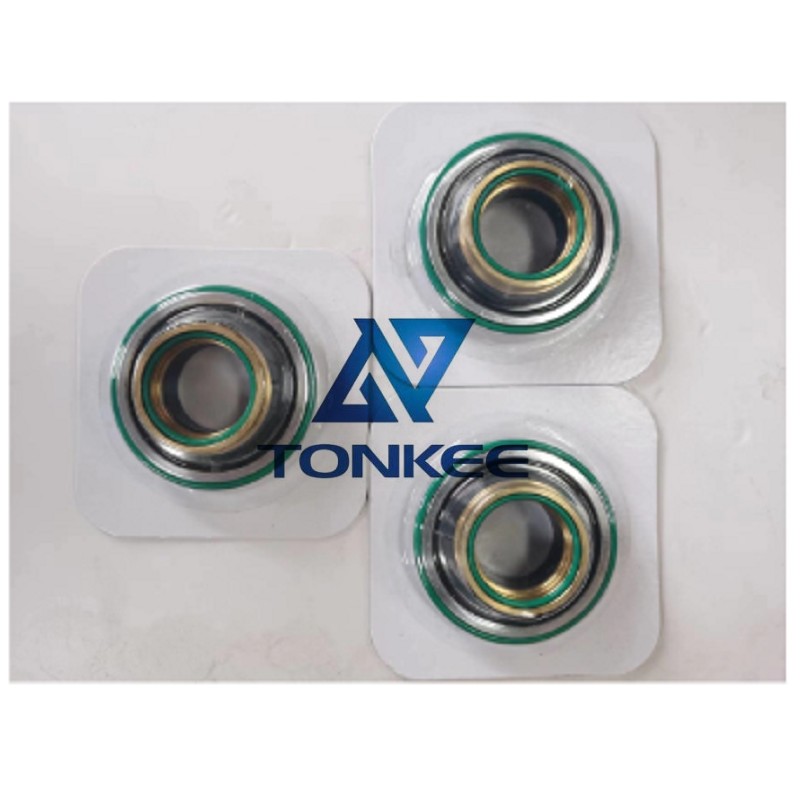

Part Type: Mechanical Seal

Design and Construction

Seal Type:

The mechanical seal is typically a cartridge type design, which offers ease of installation and replacement. It combines multiple sealing elements into a single, pre-assembled unit.

Materials:

Stationary Seal Face: Usually made of a high-quality ceramic material such as silicon carbide (SiC). Silicon carbide provides excellent wear resistance, chemical stability, and thermal conductivity, ensuring a long service life and reliable sealing performance.

Rotating Seal Face: Commonly constructed from a carbon-based material with appropriate impregnation or coating to enhance its wear resistance and compatibility with the hydraulic fluid. For example, it could be a carbon-graphite composite.

Secondary Sealing Elements: These include elastomeric O-rings or other flexible sealing materials. The O-rings are often made of nitrile rubber (NBR) for general hydraulic applications, but in some cases, depending on the fluid compatibility requirements, other materials like fluorocarbon rubber (FKM) may be used. The O-rings provide a secondary seal to prevent leakage around the mechanical seal assembly.

Spring or Bellows: The mechanical seal may incorporate a spring or bellows element to maintain the proper contact pressure between the stationary and rotating seal faces. The spring is typically made of a corrosion-resistant metal alloy such as stainless steel, while the bellows, if used, could be a metal bellows made of a suitable alloy like Inconel for high-temperature and high-pressure applications.