Preparation: Start by ensuring the machine is turned off, and all hydraulic pressure is released.

Place the wheel loader on a stable surface and secure it to prevent any accidental movement.

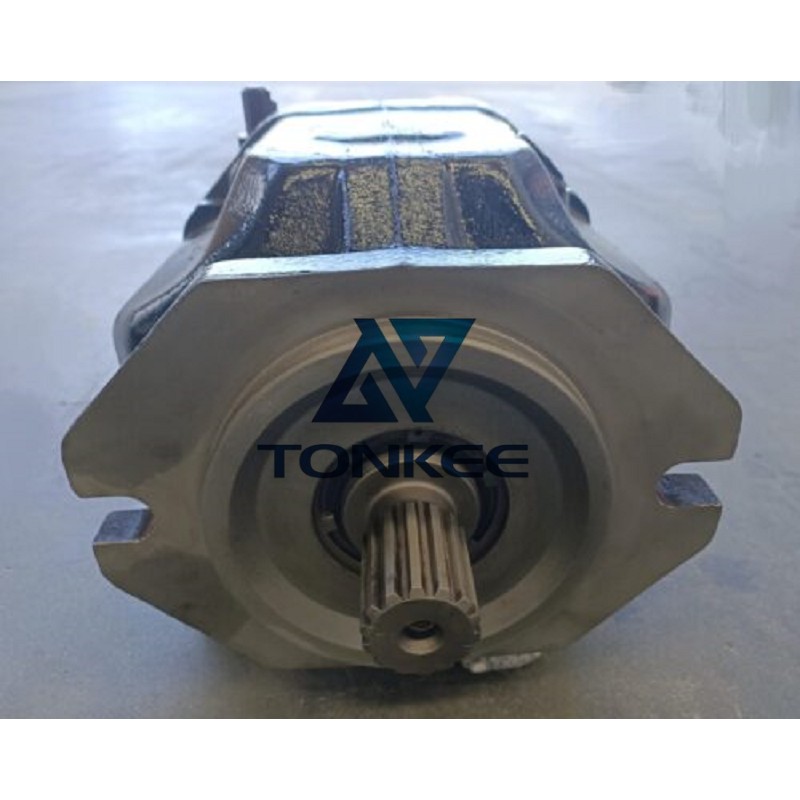

Disassembly: Carefully remove the hydraulic pump from the machine, following the manufacturer's guidelines. Take note of the pump's orientation and connections to ensure correct reinstallation later. Disassemble the pump, separating its various components.

Inspection: Thoroughly inspect each component for signs of wear, damage, or corrosion. Pay close attention to the pump housing, gears, vanes, seals, and bearings. Replace any damaged or worn-out parts with the corresponding components from the VOE 11172710 rebuild kit.

Cleaning: Clean all the components using an appropriate cleaning solvent to remove dirt, debris, and old lubricants. Ensure that all parts are completely free of contaminants before reassembly.

Reassembly: Follow the provided specifications and instructions to assemble the hydraulic pump. Lubricate the components with the recommended hydraulic oil or grease during reassembly. Pay attention to the correct alignment and torque specifications for each component.

Testing: Once the pump is reassembled, it is essential to test its functionality.

Connect the hydraulic pump to the machine's hydraulic system and conduct a series of tests to ensure proper operation. Verify that the pump generates the required hydraulic pressure and there are no leaks or abnormal noises.

Installation: If the rebuilt pump passes all tests, reinstall it into the machine following the manufacturer's guidelines. Make sure all connections are secure and properly tightened.